Paper 40:

Nachimani Charde ‘Joining the austenitic stainless steels with surface corroded carbon steels in resistance spot welding’ 2023 (in-press)

(Impact Factor : 4.344)

Paper 39:

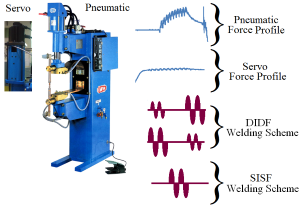

Nachimani Charde ‘Acoustic Emission of Mild Expulsion in Resistance Spot Welding : Comparing The Force Profiles of Pneumatic versus Servo Compressing System’

2023 (in-press) (Impact Factor : 3.762)

Paper 38:

Nachimani Charde ‘Dual Current Excitation using 304 Austenitic Stainless Steel in Servo Controlled Resistance Spot Welding’ 2023 (in-press)

(Impact Factor : 2.432)

Paper 37:

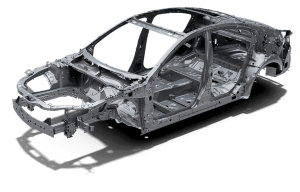

Nachimani Charde, Farazila Yusof and Rajprasad Rajkumar ‘Material characterizations of mild steels, stainless steels and both steels mixed joints under resistance spot welding

(2 mm sheets)’ International Journal of Advanced Manufacturing Technology, pp 373-384, Vol 75, Issue 1, 2014. (ISSN: 0268-3768) (ISI-Web of Science, Science Citation Expended Index)

(Impact Factor : 3.563)

(Impact Factor : 3.563)

Paper 36:

Nachimani Charde ‘Converting the pneumatic to servo based system in RSW: analyzing the dissimilar weld joints for welding schemes’

Journal of the Brazilian Society of Mechanical Sciences and Engineering, 2018. (ISI-Web of Science, Science Citation Expended Index)

(Impact Factor : 2.361)

(Impact Factor : 2.361)

Paper 35:

Nachimani Charde ‘Resistance spot welds of austenitic stainless steel, part 3: 1 & 1, 1 & 2 and 2 & 2 mm thickness of weld joints’ Indian Welding Journal, 2016.

Paper 34:

Nachimani Charde ‘Techniques for the improvement of carbon steels welds: under the SISF and DIDF welding schemes using pneumatic and servo based

electrode actuating systems in resistance spot’ International Journal of Advanced Manufacturing Technology, August 2015. (ISI-Web of Science, Science Citation Expended Index)

(Impact Factor : 3.563)

(Impact Factor : 3.563)

Paper 33:

Nachimani Charde, Roslina Ahmad, Nor Ishida Zainal Abidin ‘Interpreting the weld formations using acoustic emission for the carbon steels and

stainless steels welds in servo-based resistance spot welding’ International Journal of Advanced Manufacturing Technology, Nov 2015. (ISI-Web of Science, Science Citation Expended Index)

(Impact Factor : 3.563)

(Impact Factor : 3.563)

Paper 32:

Nachimani Charde ‘Post crack propagation of tensile shear test: analyzing the carbon steel, stainless steel and mixed steel welds in resistance spot welding’

Journal of Failure Analysis and Prevention, August 2016. (ISSN: 1547-7029)(ISI-Web of Science, Emerging Sources Citation Index)

Paper 31:

Nachimani Charde ‘Resistance spot welds of austenitic stainless steel, part 2: signals measurement, dynamic resistance, electrically generated forging force,

metallurgy and hardness distribution analysis’ Indian Welding Journal, Vol 49, No1, 2016.

Paper 30:

Nachimani Charde ‘Investigating the copper-chromium electrodes deformation during the welding process of resistance spot welding’ Journal of Canada Welding Association, Page 32-38, February 2016.

Paper 29:

Nachimani Charde ‘Spot weld growth on medium carbon steel (Part 2)’, Welding and Materials Testing, 2016. (ISSN: 1453-0392)

Paper 28:

Nachimani Charde ‘Performance analysis of a pneumatic to servo converted system for the electrode actuation in resistance spot welding using

304L austenitic stainless steel’ Journal of Central South University, 23, Page 1-10. (ISSN: 2095-2899) (ISI-Web of Science, Science Citation Expended Index)

(Impact Factor : 2.392)

(Impact Factor : 2.392)

Paper 27:

Nachimani Charde ‘Converting the pneumatic to servo based system in rsw: analyzing the electrode caps deformation’ Proceedings of the Institution of Mechanical Engineers UK,

Part B: Journal of Engineering Manufacture, Page: 1-5, 2015. (ISSN: 09544054) (ISI-Web of Science, Science Citation Expended Index)

(Impact Factor : 2.759)

(Impact Factor : 2.759)

Paper 26:

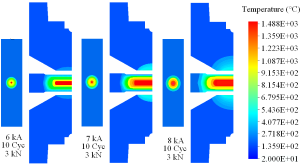

Nachimani Charde ‘Resistance spot welds of 304l austenitic stainless steel,

part 1: fundamental, simulation, weld growth, tensile strength and failure mode analysis’ Indian Welding Journal, Vol 48, No. 2 April, 2015. (ISSN: 0046-9092)

Paper 25:

Nachimani Charde, Farazila Yusof and Rajprasad Rajkumar ‘Investigating the indentation, degrading and deterioration of electrodes using carbon and stainless steels welds in resistance spot welding’ Welding and Cutting.

(ISSN: 0256-2499)

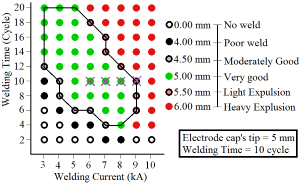

Paper 24: Nachimani Charde ‘Effect of spot welding variables on nugget size and bond strength of 304 austenitic stainless steel’ Australasian Welding Journal, 57.3, Page: 39-44, 2012. (ISSN: 1583-7904)

Paper 23:

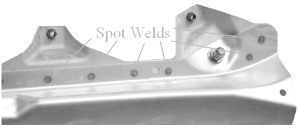

Aravinthan Arumugam and Nachimani Charde ‘Analysis of spot weld growth on mild and stainless steel’ Welding Journal, Page: 143-147, August, 2011.

(ISSN: 0043-2296) (ISI-Web of Science, Science Citation)

(Impact Factor : 2.217)

(Impact Factor : 2.217)

Paper 22:

Aravinthan Arumugam and Nachimani Charde ‘A metallurgical study of spot weld growth on mild steel with 1 mm and 2 mm thicknesses’ Journal - Vol. 72, No. 4, Page: 32–36, Journal of Institution of Engineers Malaysia, 2011. (ISSN: 0126-513X)

Paper 21:

Nachimani Charde ‘Exploring the electrodes alignment and mushrooming effects on weld geometry of dissimilar steels during the spot welding process’ Sadhana,

pp 1563-1572, Vol 39, Issue 6, 2014.(ISSN: 0256-2499) (ISI-Web of Science, Science Citation Expended Index)

(Impact Factor : 1.214)

(Impact Factor : 1.214)

Paper 20:

Nachimani Charde, ‘Forging force in resistance spot welding: analyzing the electrically generated forging force for two different electrode actuations’

International Journal of Advanced Manufacturing Technology, August 2015. (ISI-Web of Science, Science Citation Expended Index)

(Impact Factor : 3.563)

(Impact Factor : 3.563)

Paper 19: Nachimani Charde ‘Spot weld growth on 304L austenitic stainless steel for equal and unequal thickness’ Caspian Journal of Applied Sciences Research, Page: 79-87, 2012.

(ISSN: 2251-9114) (ISI-Web of Science, Master List)

Paper 18:

Nachimani Charde ‘Analyzing the force and current profiles using pneumatic and servo based-electrode actuation system for resistance spot welding’ Caspian Journal of Applied Sciences Research.

(ISSN: 2251-9114) (ISI-Web of Science, Master List)

Paper 17:

Nachimani Charde ‘Old philosophers and the universe structure-philosophy of Jaimini, 4000 BC’ Electronics World – UK, Page: 44-45, May 2007.

(ISSN: 1365-4675) (ISI-Web of Science, Science Citation Expended Index)

Paper 16: Nachimani Charde ‘Electrical power divider rule’ Electronics World – UK, Page: 50, July 2006. (ISSN: 1365-4675) (ISI-Web of Science, Science Citation Expended Index)

Paper 15: Nachimani Charde ‘Microstructure and fatigue properties of dissimilar spot weld joints of AISI 304 and AISI 1008’ International Journal of Automotive and Mechanical Engineering, Page: 1–14, 2013.

(ISSN: 2229-8649) (Scopus/DOAJ)

Paper 14:

C. Nachimani ‘Spot weld growth on medium carbon steel (Part 1)’ International Journal of Mechanical and Materials Engineering, Vol.44, No. 7, Page: 36–40, 2012. (ISSN: 1823-0334)

(ISI-Web of Science, Emerging Sources Citation Index)

Paper 13:

Nachimani Charde and R.K Rajkumar ‘Investigating spot weld growth on austenitic stainless steel (2mm)’ Journal of Engineering Science and Technology, Vol. 8, No. 1, Page: 69 – 76, Feb 2013.

(ISSN: 2231-8380) (ISI-Web of Science, Emerging Sources Citation Index)

Paper 12:

Nachimani Charde ‘An experimental investigation on spot weld growth on dissimilar joints of 304L austenitic stainless steel and medium carbon steel (Part 1)’ – International Journal of Advances in Applied Sciences, Page: 31-40, Jan 2013. (ISSN: 2252-8814)

Paper 11:

Nachimani Charde ‘Characterization of spot welds growth on dissimilar joints with different thicknesses’ Journal of Mechanical Engineering and Sciences, Volume 2, Page: 172–180, June 2012.

(ISSN: 2231-8380) (ISI-Web of Science, Emerging Sources Citation Index)

Paper 10:

Nachimani Charde ‘Effects of electrode deformation on carbon steel weld geometry of resistance spot welding’ International Journal of Advance Innovations, Thoughts and Ideas, Page: 5-12, Sept. 2012.

(ISSN: 2277-1891)

Paper 9:

Aravinthan Arumugam and Nachimani Charde ‘A mechanical study of spot weld growth in mild steel, 302 austenitic stainless steel and both materials joined’ Journal of Material Science and Engineering A1, Page: 172–180, 2011.

(ISSN: 2161-6221)

Paper 8:

Nachimani Charde and Aravinthan Arumugam ‘An analysis of resistance spot weld growth on mild and stainless steel with 1mm and 2mm thicknesses’ – ICASEIT 2011, International Journal of Advance Science, Engineering and IT, Vol. 1, No 5, Pages: 549 –553, 2011.

(ISSN: 2088-5334)

Paper 7:

R.K Rajkumar, Fatin Hamimi and Nachimani Charde ‘Investigating the dissimilar weld joints of AISI 302 austenitic stainless steel and low carbon steel’ – International Journal of Scientific and Research Publication, Page: 1-5, 2012. (ISSN: 2250-3153)

Paper 6:

Nachimani Charde ‘Effects of electrode deformation on 304 austenitic stainless steel weld geometry of resistance spot welding’ Journal of Mechanical Engineering and Sciences, Volume 2, Page: 261–270, Dec 2012.

(ISSN: 2231-8380) (Scopus/DOAJ)

Paper 5:

Nachimani Charde ‘Spot weld growth on 304L (2b) austenitic stainless steel: a review paper’ Journal of Mechanical and Industrial Engineering Research, Vol 3, Page: 1-22, March 2013.

(ISSN: 2304-7461)

Paper 4:

Nachimani Charde and D. Komalavalli ‘Introduction to supreme number (Part 1)’–ICASEIT 2011, International Journal of Advance Science, Engineering and IT, Vol. 1, No 1, Pages: 12–16, 2011.

(ISSN: 2088-5334)

Paper 3: Nachimani Charde and D. Komalavalli ‘Introduction to supreme number (Part 2)’–Electronic International Interdisciplinary Research Journal, Pages: 70–83, Dec 2012. (ISSN: 2277-8721)

Paper 2:

Fatin Hamimi, Abu Samah and Nachimani Charde ‘Effect of rain attenuations on free space optical transmission in Kuala Lumpur’, International Journal of Advance Science, Engineering and IT, Vol. 1, No 4, Pages: 337–341, 2011.

(ISSN: 2088-5334)

Paper 1:

Nachimani Charde ‘Experimental analysis of spot welds growth on carbon steels using pneumatics-driven 75kVA spot welder’ Journal of Mechanical and Industrial Engineering Research, 2014.

(ISSN: 2304-7461)

Conference Publications (Abstract and Proceeding)

Paper 7:

Nachimani Charde ‘Investigating spot weld growth on 304L (2B) stainless steel (2mm)’ 8thInternational Materials Technology Conference and Exhibition – KL Malaysia, 2012.

(Abstract)

Paper 6:

Nachimani Charde, F.H. Hamat @Mustafa, Rajkumar Rajprasad ‘Effects of light haze and thick fog attenuations on FSO transmission in Petaling Jaya’ Malaysia, IEEE Conference on Sustainable Utilization and Development in Engineering and Technology – UNMC Malaysia, 2011.

(Abstract)

Paper 5:

Fatin Hamimi, Abu Samah and Nachimani Charde ‘Effect of rain attenuations on free space optical transmission in Kuala Lumpur’ International Conference on Advance Science, Engineering and IT – UKM Malaysia, 2011. (ISBN: 978-983-42366-4-9)

(Proceeding)

Paper 4:

Nachimani Charde and D. Komalavalli ‘Introduction to supreme number (Part 1)’ International Conference on Advance Science, Engineering and IT–UKM Malaysia, 2011. (ISBN: 978-983-42366-4-9)

(Proceeding)

Paper 3:

Nachimani Charde and Aravinthan Arumugam ‘An analysis of resistance spot weld growth on mild and stainless steel with 1 mm and 2 mm thicknesses’ International Conference on Advance Science, Engineering and IT–UKM Malaysia, 2011. (ISBN: 978-983-42366-4-9)

(Proceeding)

Paper 2:

Nachimani Charde and Aravinthan Arumugam ‘A mechanical study of spot weld growth in the 1 mm thickness of mild steel, 302 austenitic stainless steel and both materials joined’ 7th International Materials Technology Conference and Exhibition – Sarawak Malaysia, 2010.

(Abstract)

Paper 1:

Nachimani Charde and Aravinthan Arumugam ‘A metallurgical study of spot weld growth of mild and 302 authentic stainless steel with different thicknesses’ International Conference on Materials Processing Technology– Bangkok Thailand, 2010.

(Abstract)